Amorphis refracty materiae sunt late in multis summus temperatus industriae agri ex eorum optimum scelerisque insulatione perfi...

READ MORERefractionis indefinitae Castables

Proprietas: Societas nostra refractoria castella indefinita fabricatur per mechanismum cohaesionis, polymerizationis, flocculationis et ceramicae cum materiarum refractoriae summae puritatis et GENERALIS, Opportunam constructionem, magnam integritatem, resistentiam, resistentiam, usum vitae lineae, aliaque lineamenta. .

- Product Parameter

- Gratuitas Quotes

Typical Chemical and Physical Index:

| Alumina cavum Ball Castables HG-165 | Alumina cavum Ball Castables HG-160 | Princeps Fortitudo Mullite Leve Castables HG-145 | Princeps Fortitudo Mullite Leve Castables HG-140 | Leve Mullite Castables HG-135 | Leve Mullite Castables HG-130 | ||

| Operating Temperatus | 1650 | 1600 | 1450 | 1400 | 1350 | 1300 | |

| Mole densitas (g/cm) | 1.5 | 1.5 | 1.7 | 1.7 | 1.4 | 1.4 | |

| Cogo fortitudo (Mpa) | 110℃×24h | 7.5 | 17 | 25 | 25 | 6 | 5.5 |

| 1300℃×3h | 20 | 22 | 20 | 20 | 5 | 5 | |

| Mutationes Post filum incendens % ℃×3h | 0.4 (1600) | 0.5(MD) | 0.6(1450) | 0.8 (1400) | 0.7 (1350) | 0.7 (1300) | |

| Scelerisque Conductivity (w/m.k) | 400℃ | 0.42 | 0.42 | 0.58 | 0.58 | 0.40 | 0.38 |

| 800℃ | 0.48 | 0.48 | 0.64 | 0.64 | 0.45 | 0.43 | |

| Chemical Components | Al2O3 ≥ | 98 | 94 | 70 | 68 | 65 | 65 |

| Fe2O3 ≤ | 0.3 | 0.3 | 0.8 | 0.9 | 0.9 | 1.0 | |

| PERFUSORIUS Caloris Insulating et Thermal-Insulating Castables | ||||||||

| HG-130 | HG-125 | HG-120 | HG-110 | HG-100 | HG-90 | HG-80 | ||

| Operating Temperatus | 1300 | 1250 | 1200 | 1100 | 1000 | 900 | 800 | |

| Mole densitas (g/cm) | 1.4 | 1.3 | 1.2 | 1.1 | 1.0 | 0.8 | 0.6 | |

| Compressive fortitudo 1000℃×3h Mpa | 5 | 6 | 4 | 4 | 4 | 1.7 (900℃×3h) | 0.6 (800℃×3h) | |

| Mutationes Post filum incendens % ℃×3h | 0.6 (1300) | 0.7 (1250) | 0.6 (1200) | 0.6 (1100) | 0.5 (1000) | 0.7 (900) | 0.5 (800) | |

| Scelerisque Conductivity 600℃ w/m.k | 0.36 | 0.33 | 0.32 | 0.30 | 0.28 | 0.25 | 0.17 | |

| Chemical Components % | AL2O3 ≥ | 43 | 42 | 38 | 32 | 30 | 28 | 28 |

| Clay Bonding Plasticity | Summus Temperatus Refractory Plasticity | Mullite Ignis Plasticitas | Corundum Refractory Plasticity | Pii Carbide Ignis Plasticity | ||

| Mole densitas (g/cm) | 2.35 | 2.60 | 2.60 | 3.00 | 2.60 | |

| Ignis resistentia ℃> | 1700 | 1720 | 1750 | 1790 | 1790 | |

| Cogo fortitudo (Mpa) | 110℃×24h | 15 | 40 | 42 | 45 | 45 |

| 600℃×3h | 20 | 60 | 65 | 65 | 68 | |

| 1300℃×3h | 35 | 70 | 75 | 80 | 80 | |

| Linearibus Mutationem reheat% ℃×3h | ±0.2 (1400) | ±0.3 (1400) | ±0.3 (1450) | ±0.3 (1500) | ±0.3 (1400) | |

| Concursores stabilitatis scelerisque / tempora | 30 | 30 | 30 | 30 | 30 | |

| Chemical Components | Al2O3 ≥ | 55 | 72 | 73 | 92 | - |

| Fe2O3 % ≤ | 1.2 | 1.1 | 0.8 | 0.3 | - | |

| SiO2 ≥ | - | - | - | - | 71 | |

-

-

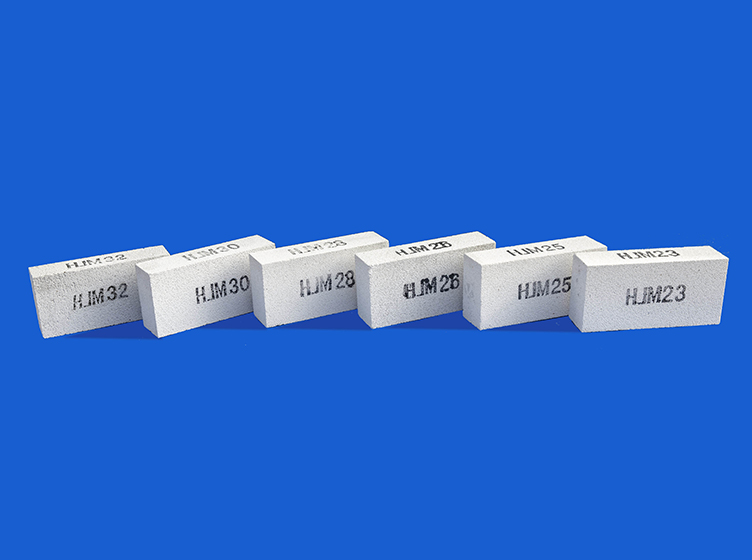

In vestibulum processus Insulating Refractia Bricks Et lectio rudis materiae est crucial et directe afficit perficientur...

READ MORE -

Ad perficientur Insulating Refractia Bricks Est directe affectus genus rudis materiae, praesertim secundum chemical comp...

READ MORE -

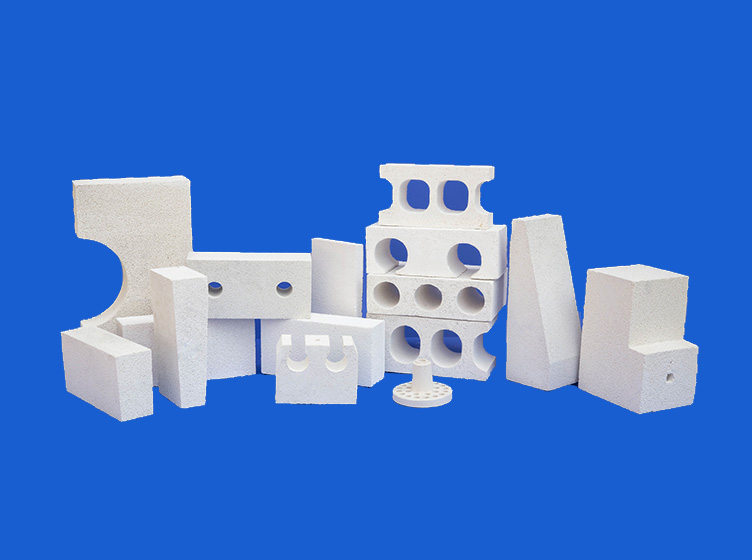

Refractior materiae late adhibentur in ambitibus calidis, praesertim in industria sicut metallurgia, industria et potenti...

READ MORE -

Hodiernae applicationes industriae, vires et effectus insulating refractariis lateribus directe afficit salutem et produ...

READ MORE