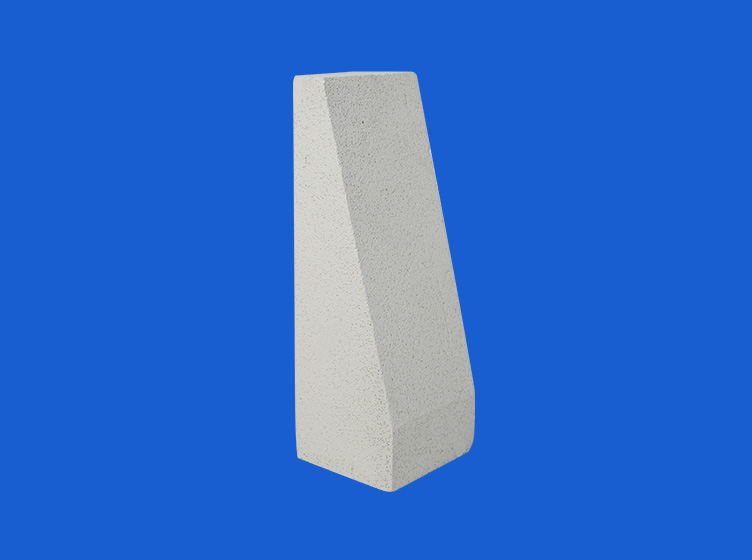

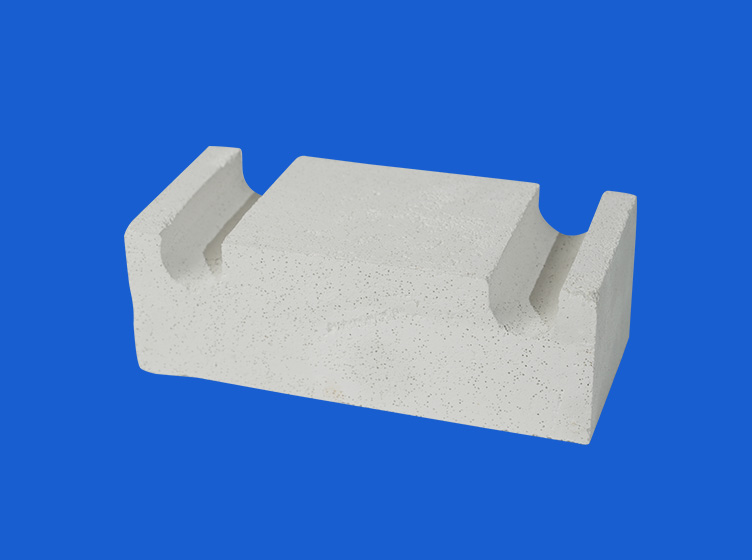

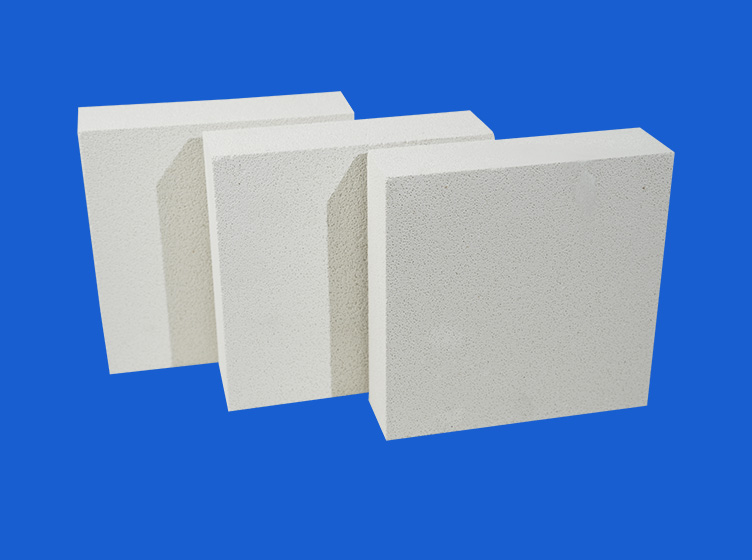

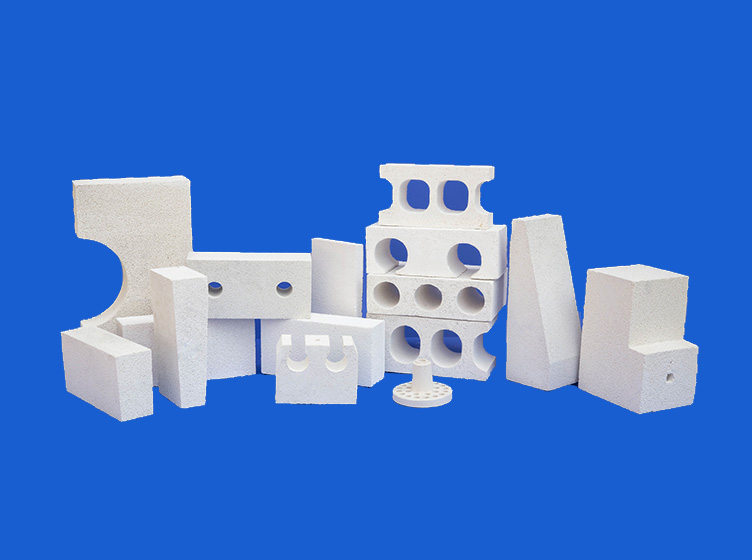

Amorphis refracty materiae sunt late in multis summus temperatus industriae agri ex eorum optimum scelerisque insulatione perfi...

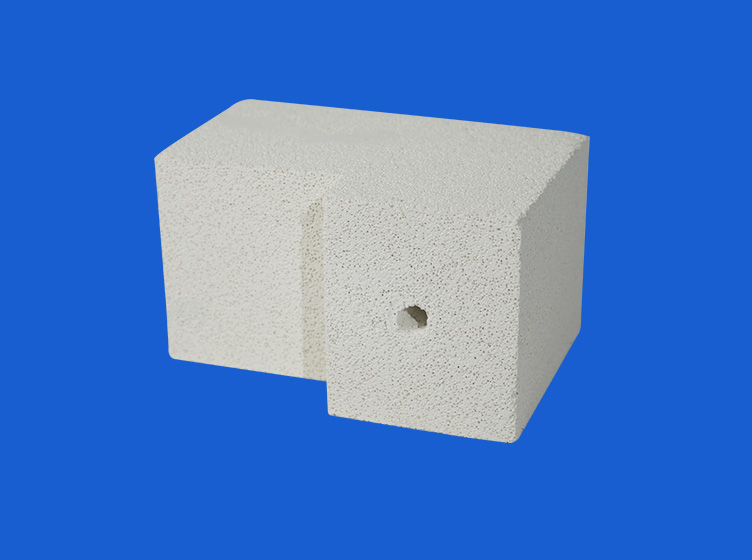

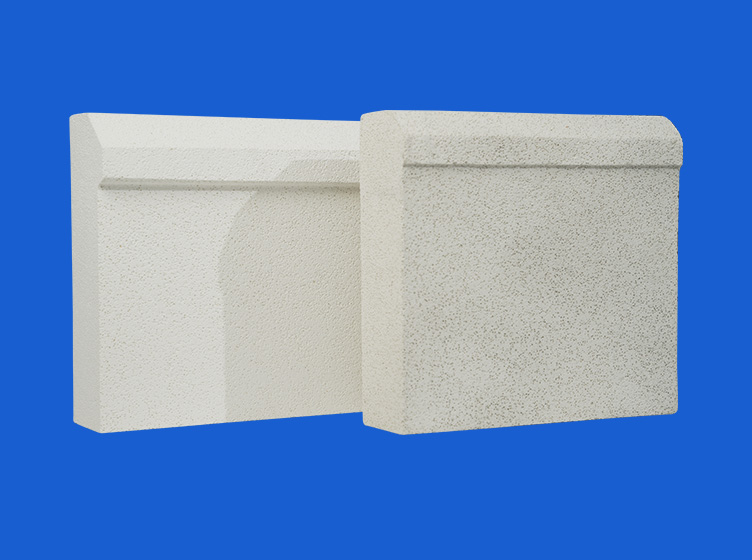

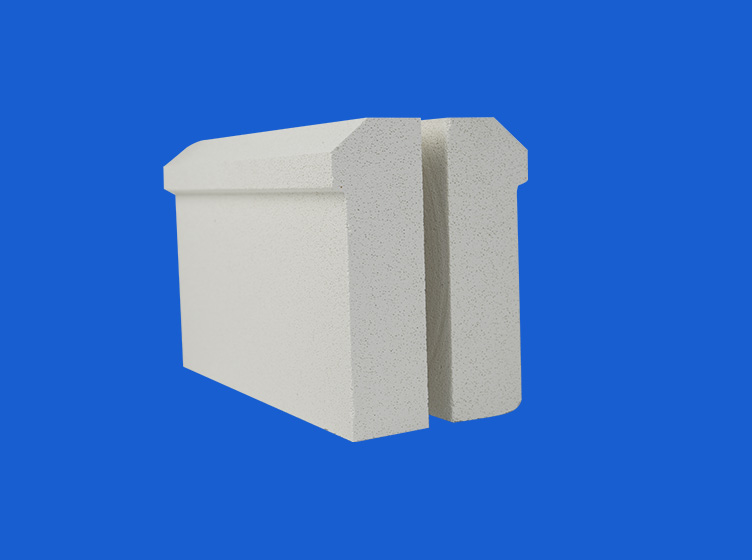

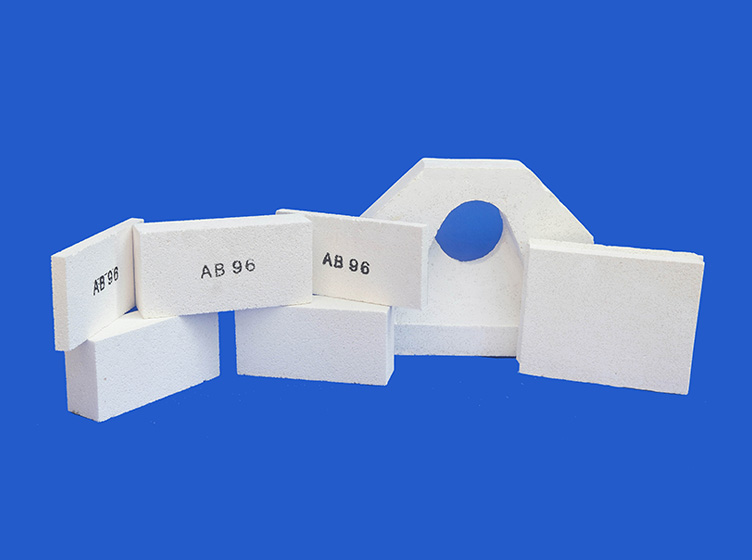

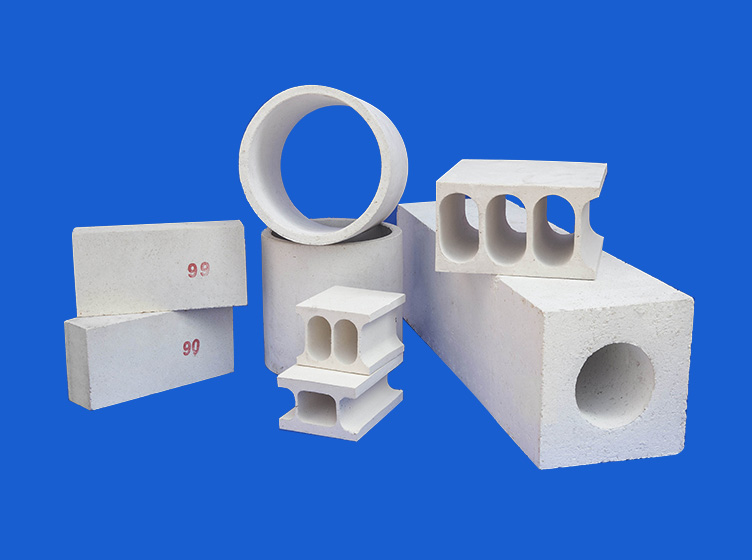

READ MOREAnti-carburizing Brick and High Alumina, Low ferreum Bricks

- Product Parameter

- Gratuitas Quotes

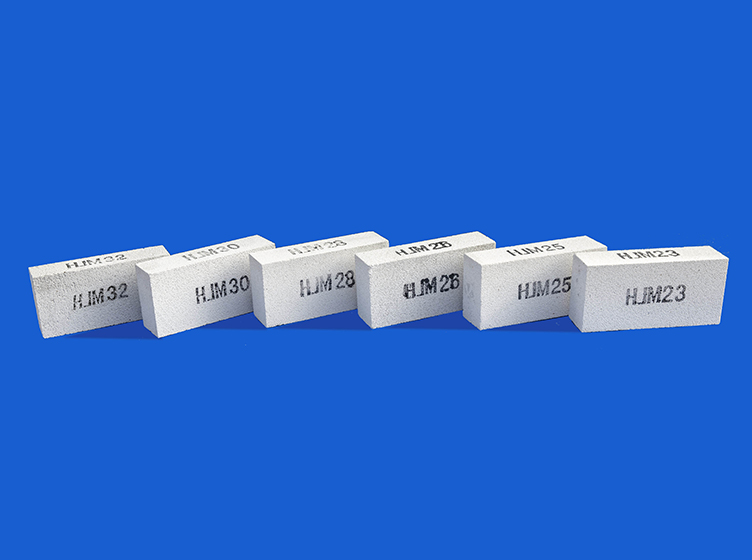

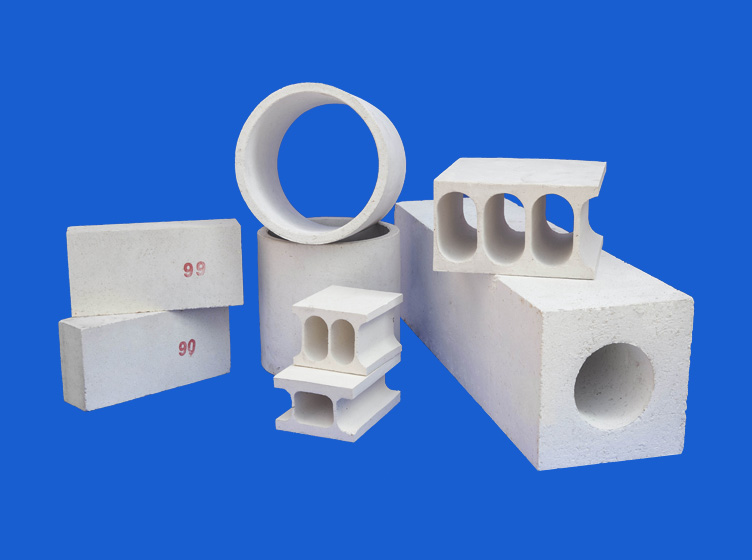

Typical Chemical and Physical Index:

| KST0.48 | KST0.6 | KST0.8 | KST1.0 | KST2.0 | KST2.5 | ||

| Temperature operating | 1180 | 1250 | 1300 | 1350 | 1350 | 1500 | |

| Mole densitas (g/cm) | 0.48 | 0.6 | 0.8 | 1.0 | 2.0 | 2.5 | |

| Reburning Line Change hr% ≤ | 1180×12 0.5 | 1250×12 0.5 | 1300×12 0.4 | 1300×12 0.4 | 1300×12 0.2 | 1500×12 0.2 | |

| Normalis Temperature Compressive Fortitudo (Mpa) | 1.0 | 1.2 | 1.8 | 3.0 | 25 | 35 | |

| Flexurae Fortitudo in volutpat Temperature (Mpa) | 0.7 | 0.9 | 1.2 | 1.6 | 8 | 10 | |

| Scelerisque Conductivity 350±20℃ w/m.k | 0.18 | 0.21 | 0.35 | 0.45 | 1.6 |

| |

| Minuendo onus Temperature | 1200 | 1280 | 1350 | 1400 | 1400 | 1500 | |

| Chemical Components % | Al2O3≥ | 37 | 42 | 46 | 48 | 50 | 65 |

| Fe2O3≤ | 0.8 | 0.7 | 0.7 | 0.7 | 0.7 | 0.5 | |

| SiO2≥ | 61 | 56 | 52 | 50 | 48 | 33 | |

-

-

In vestibulum processus Insulating Refractia Bricks Et lectio rudis materiae est crucial et directe afficit perficientur...

READ MORE -

Ad perficientur Insulating Refractia Bricks Est directe affectus genus rudis materiae, praesertim secundum chemical comp...

READ MORE -

Refractior materiae late adhibentur in ambitibus calidis, praesertim in industria sicut metallurgia, industria et potenti...

READ MORE -

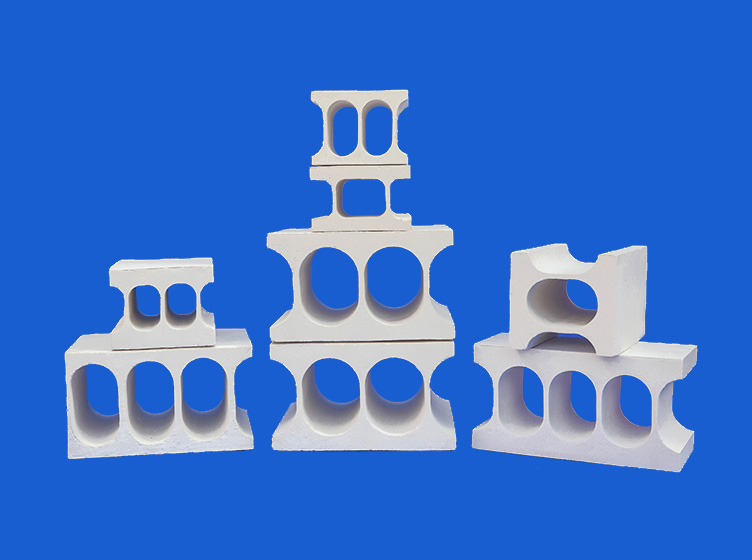

Hodiernae applicationes industriae, vires et effectus insulating refractariis lateribus directe afficit salutem et produ...

READ MORE